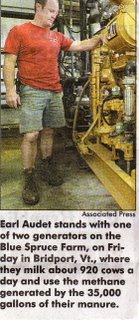

BRIDPORT, Vt. - The cows at the Audet family's Blue Spruce Farm make nearly 9,000 gallons of milk a day - and about 35,000 gallons of manure.

It's long been the milk that pays, in the form of the checks farmers receive from dairy wholesalers who bottle it or turn it into cheese and other products. But now the Audets - brothers Eugene, Ernie and Earl and their wives - have figured out a way to make the manure pay as well. They're using it to generate electricity.

Mixed in with the smelly gasses released by a pile of manure is a main ingredient that is odor-free: methane. With the help of their power company, Central Vermont Public Service Corp., the Audets have devised a way to extract the methane from the manure and pipe it to a generator.

They make enough electricity to power 300 to 400 average Vermont homes. It's renewable energy - the cows just keep on giving. The engine that powers the Audets' generator is shut down occasionally for oil changes, but in 2005, it ran 97 percent of the time, said Dave Dunn, a senior energy consultant with CVPS.

They make enough electricity to power 300 to 400 average Vermont homes. It's renewable energy - the cows just keep on giving. The engine that powers the Audets' generator is shut down occasionally for oil changes, but in 2005, it ran 97 percent of the time, said Dave Dunn, a senior energy consultant with CVPS.

Electricity has created an important new income stream for the Audets' farm at a time when low wholesale milk prices have squeezed their margin. The utility pays 95 percent of the going New England wholesale power price for electricity from the Audets' generator.

In addition, the utility charges customers willing to pay it a 4-cents-per-kilowatt-hour premium for renewable energy and then turns the money over to the Audets. So far, more than 3,000 CVPS customers have signed up to pay the premium.

The bottom line, given recent wholesale power prices, is more than $120,000 a year from electricity sales. When they add in other energy savings enabled by the project, the Audets expect their $1.2 million investment in project equipment to pay for itself in about seven years.

In their stalls, cows munch contentedly on a mix of hay and silage while, from their other ends, they make an occasional contribution of fuel. The animals placidly lift one hind leg and then the other as an "alley scraper" comes by to push their manure down the row and through an occasional grate to a conveyor belt below. From there the manure goes to an anaerobic- meaning oxygen-free-digester, a structure similar to a covered swimming pool. The manure spends 20 or 21 days in the digester.

Sunday, June 25, 2006

By DAVID GRAM

Associated Press

3 comments:

The old original Mother Earth News had a story about a pig farmer in,I believe South Africa, who did the same thing.

He made so much from the sale of gas and fertilizer, he could have gotten out of the hog business but he needed thier "input".

This was in the '60-'70s before that magazine turned into the pathetic rag it has become.

Now the one to read for that kind of stuff is Backwoods Home

Dennis

I have not seen Mother Earth News for about a year and it was certainly not the same as I remembered. I'll take a look at Backwoods Home Dennis, thanks for the tip. You know, it wouldn't take to many cows to provide power to all of Vermont!

Thank you for being youu

Post a Comment